Our Products

Explosion-proof Ball

This non-metallic explosion-proof material is manufactured using a specialized fire-resistant material formulation. When subjected to rapid temperature escalation, it melts to release fire-suppressant compounds, immediately inhibiting flame propagation and preventing secondary explosions.

Application Scenarios

● OIL/chemical Factory, Refinery (of oil etc.)

● Oil/chemical Transportation

● Oil/chemical Station,

High compatibility

● The balls are highly compatible with 27 chemicals, mainly flammable liquids: gasoline diesel, etc.

● Above 20 years usable life.

● High Temperature Resistance

● JT/T 1046 verifies the high compatibility.

Fiberglass Pipeline Products

Fiberglass pipes are composite material pipelines formed using the wet filament winding process, with fiberglass as the reinforcement material and epoxy resin or polyester resin as the matrix material. These pipes boast excellent corrosion resistance, making them widely used in oilfield gathering pipelines, single-well water injection pipelines, and polymer injection pipelines. They effectively solve issues such as pipeline corrosion, scaling, and wax deposition in oilfields.

Nominal diameter: DN25-DN1300

Pressure rating: 0.6-34.5 MPa

Long term service temperature: ≤ 65.5°C for anhydride based pipes, ≤ 93.3°C for aromatic amine-based pipes.

API 15HR-2016 High-Pressure Fiberglass Line Pipe SY/T 6267-2018 High-Pressure Fiberglass Line Pipe API 15LR-2001 Low-Pressure Fiberglass Line Pipe SY/T 6266-2004 Low-Pressure Fiberglass Line Pipe ISO 14692-2017 Glass-Reinforced Plastics (GRP) Piping

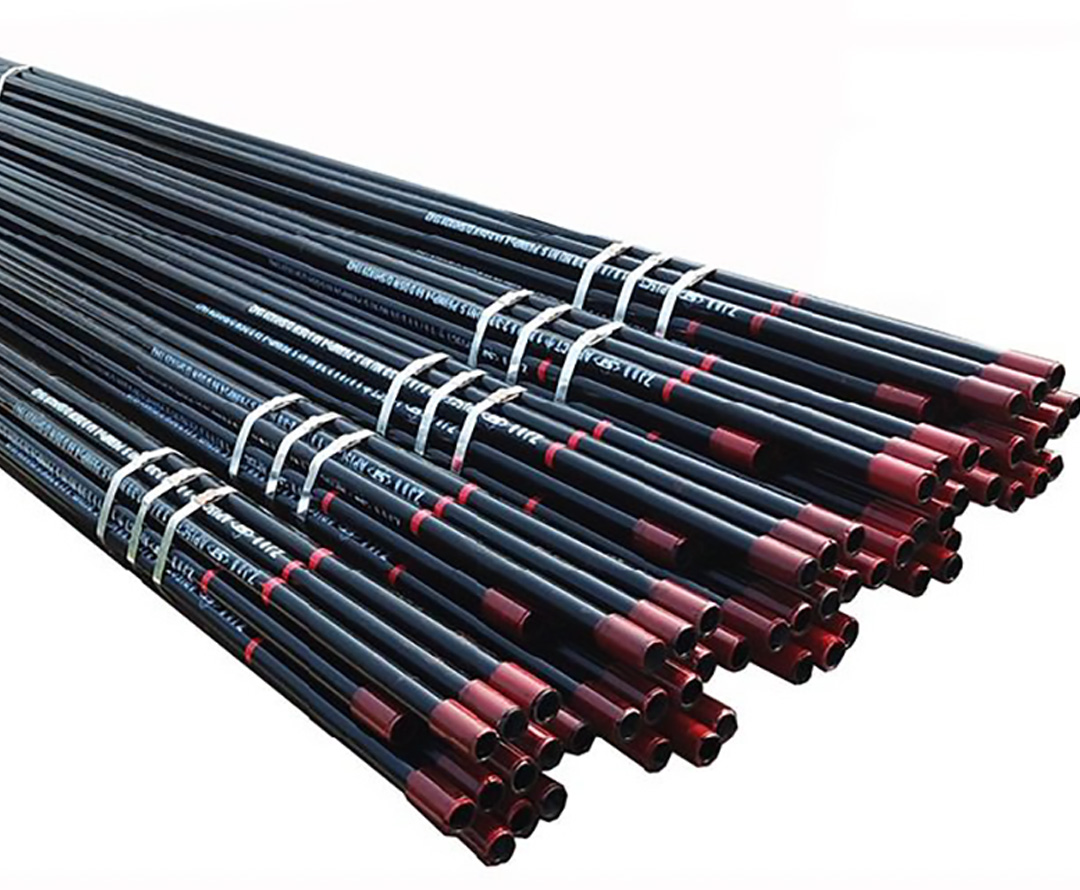

Tubing & Casing

Annual production reaches 100,000 tons.

Item Tubing Casing

OD 2 ⅜ ~ 4 ½ 4 ½ ~ 13 ⅜

GRADE J55, K55, N80, L80, P110

CONNECTION EUE, NUE STC, LTC BTC

LENGTH R2 R3

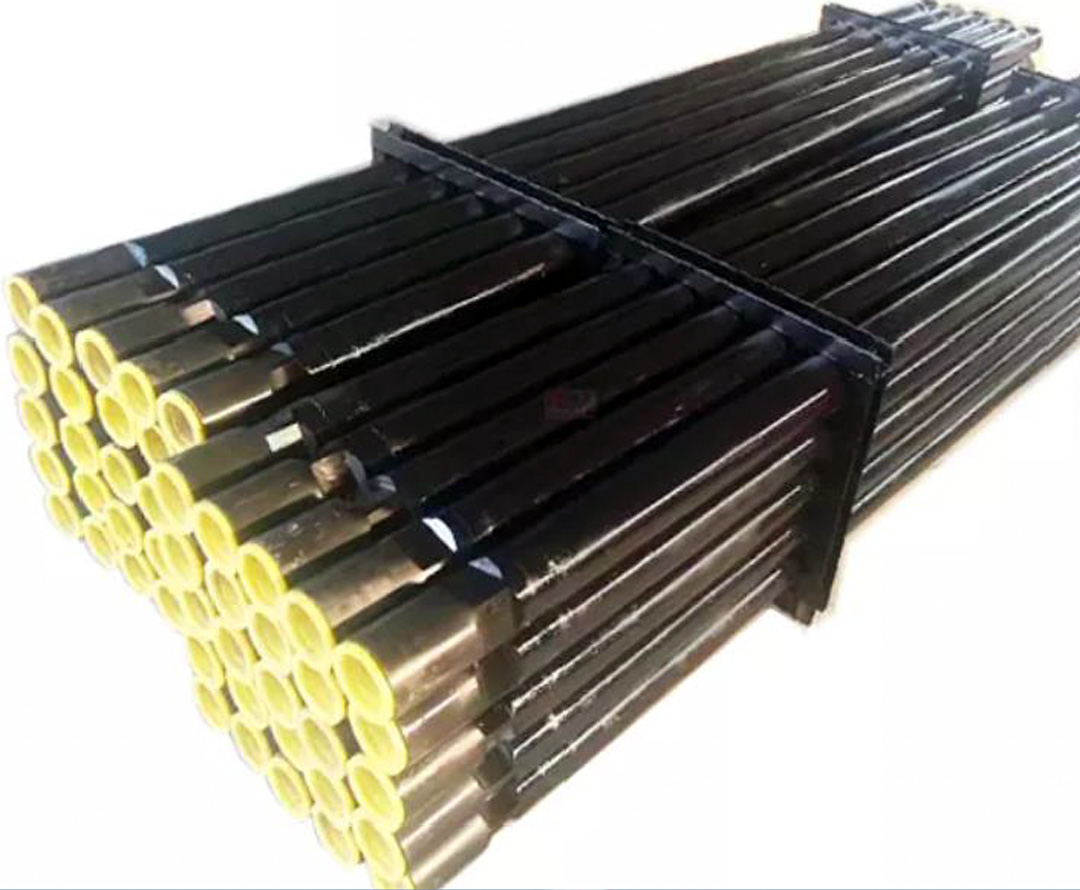

Drilling Pipe

We can provide drill pipe, high-strength drill pipe, heavy weight drill pipe, and drill collars. Hard banding process and anti-corrosion treatment is available according to client needs.

Item: Drilling Pipe

SIZE (in.): 2 ⅜ ~ 8 ⅝

Connection: NC, FH, REG

Material: E75, X95, G105, 135

Length: R2

Sucker Rod

30mm Max Diameter, 1.4g-1.5g Weight of A Single Ball, 0.45mm Min Injection Molding Thickness

1 CBM Volume unit, 45000 Balls Carrying capacity, 70Kg weight

The balls are highly compatible with 27 chemicals

Above 20 years usable life.

High Temperature Resistance

JT/T 1046 verifies the high compatibility.

The balls feature a spherical design, ensuring excellent fluidity (without affecting the speed of fuel loading and unloading). When installing the balls, we can realize full mechanization of filling, removal, and cleaning and this can solve the installation problems faced by traditional products.

Direct Link Drill Pipe

Made by welding pipe body and tool joint together by upsetting the pipe ends into the shape of a tool joint, and then threading them through heavy machinery

● Big annular, and small outside diameter: less probability of pipe-sticking during drilling work

● Big inner diameter: reduces the power loss from mud, and raise drilling efficiency

● Direct link type: the whole tool joint is shaped by repeated upsetting, producing no welding line to ensure consistent torque resistance

Petroleum Pipe Anti-Corrosion Internal Pipe Coating

300P Internal Plastic Coating (IPC) – Key Points

● Joint Development: Created with German experts for drill pipe/OCTG

● Patent-Protected: Equivalent to Tuboscope TK34, but superior in: Extreme heat resistance H₂S/CO₂ corrosion resistance

● Market Impact: Breaks U.S. monopoly in IPC technology

● Proven Performance: Used by CNOOC, Statoil, and global O&G operators

● Client Benefits:

○ 3x+ longer tool lifespan

○ Lowers drilling costs

○ Zero coating peeling/electrochemical corrosion

● Cost-Effective: Premium performance at competitive pricing

We sell many more products and you are welcome to contact us for more details.